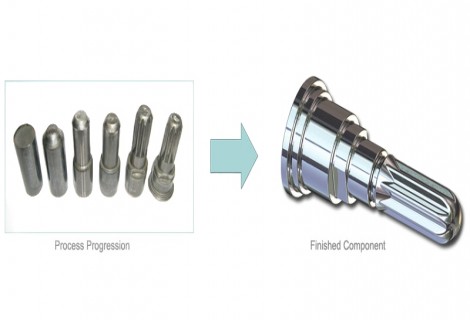

Cold Forging

Cold forging is a metal forming process where a slug or blank is deformed at room temperature. Cold forged parts can be produced using one or more single station vertical mechanical or hydraulic presses, or automated multi-station cold forming machines where the pre-formed part is transferred from one station to the next at high speed with each station performing a specific cold forming process.

MATERIALS AND PRODUCTS

There are many materials suitable for cold forging process as steel, stainless steel, aluminum, zinc, brass, bronze...

We have exclusive productive means for forging all kinds of metals, with capacity to produce parts on a wide range of sizes and shapes for various applications in industry (electronics, appliances, hardware, machinery, plumbing, telecommunications, automotive (pine nuts, solenoids, pistons, rods, seat parts, alternators, valves, anti-vibration parts, racks, etc.)

Cold Forging Advantages (Vs hot forging)

- High productivity

- Increased dimensional control

- Cost effective

- Improvement of mechanical properties

- Excellent dimensional accuracy and surface quality

- Eco-friendly