Gravity / pressure die Casting

Gravity / pressure die casting, is widely used for the manufacture of castings parts made of non-ferrous alloys such as aluminum, copper, magnesium or zinc. For this type of casting, metal is poured at atmospheric pressure in a permanent mold (which is not destroyed) made from two machined steel blocks and the cavity, will form the final part.

The molds for gravity casting are usually made of cast iron or steel and are simple in construction and most of them are operated manually although, for high volume production, pneumatic or hydraulic mechanisms are employed to open and close the molds in a preset cycle, though metal pouring and casting removal may still be manual.

MATERIALS AND PRODUCTS

This process is allow to work with non-ferrous materials as aluminum, copper, magnesium or zinc alloys because permanent mold usually are made with iron or steel. However we can manufacture with irons and steels using graphite molds.

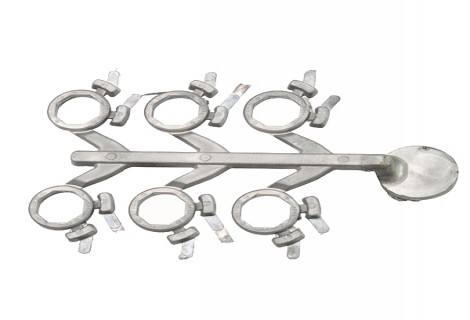

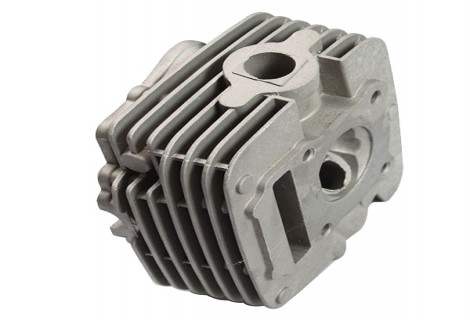

By gravity casting can be produced a big quantity of pieces with a high quality at low cost, for these reasons this process is commonly used for automotive parts but besides, it is used for manufacture industrial equipment, parts for power transmission, casings of any kind, for cable rope hubs… Some parts manufactured by this process are engine brackets, intake pipes, valve bodies, actuator bodies, cylinder heads, junction boxes, knuckles, impellers, brake calipers, compressor parts, torque rod, flanges, manifolds, housings, covers, electrical fittings parts...