Abrasive jet cutting

Water jet cutting is a process that uses a high pressure and speed jet of water to cut a wide variety of materials. According to the material to be cut there are two principal types: pure water jet that uses only water and abrasive jet which use a mixture of water and abrasive to cut hard materials. The equipment required for this process consists of a pool of water, nozzle, cooling center, warehouses for abrasives, decalcification, and a purifier of abrasives.

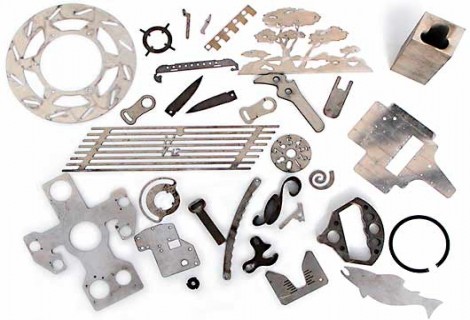

MATERIALS AND PRODUCTS

Water jet cutter works in virtually all materials except hard ceramics. Due to no produces heat affected zones some materials as rubber, plastics, foam or fabric can be cut by this method, without the need of add abrasives to water.

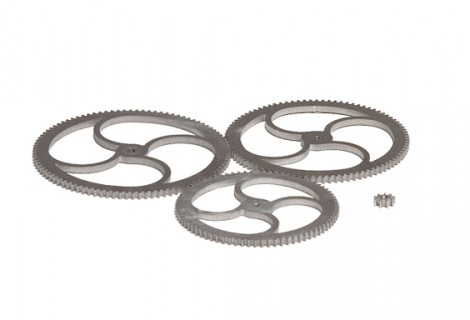

Abrasive jet are capable to cut harder materials or with a high melting temperature such as composites, tool steel, titanium, Inconel alloys inclusive some ceramics as marble and granite.

This process can be used in practically all industries thanks to his versatility such as aerospace industry (high strength aluminum or titanium), automotive (brake shoes for example), alimentary, textile and footwear (to cut leather, rubber, fabric…) are only some examples.