Laser cutting

The laser cutting process uses a laser light, which has a very high energy density, to cut the material. Materials employed in this method are sheet of carbon steel, aluminum, stainless steel, copper, magnesium, titanium… In areas covered by this light sheet material melts. Material is removed by applying a pressurized gas, usually argon, oxygen or nitrogen.

Laser cutting is a high accuracy operation helped by a computer numerical control system (CNC). It’s especially recommended to cut low thickness sheet (under 2 mm) but it is capable to cut up to 1 inch (25 mm).

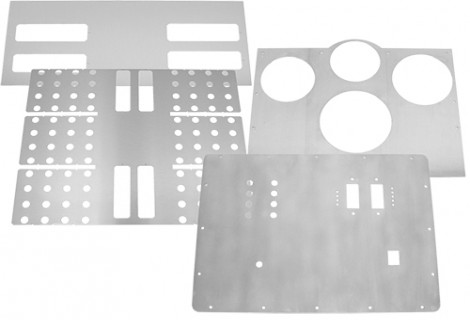

Laser cutting has several advantages. It allows creating a silhouette adjusted figures. This is an automated robotized procedure. During laser cutting, little material is lost. Moreover, a stylus or laser head itself can carry out different cuts of different sizes and shapes.

MATERIALS AND PRODUCTS

Laser cutting is suitable for different types of material as metals, paper, fabric or wood. Thought more used metals is:

- Carbon steel

- Aluminum

- Stainless steel

- Copper

- Magnesium

- Titanium

Parts made through laser cutting process are used in various fields and sectors such as automotive and household appliances, aviation, agro-machinery components, food machinery components, decorative elements, advertisement items, urban furniture or prototypes for engineering.