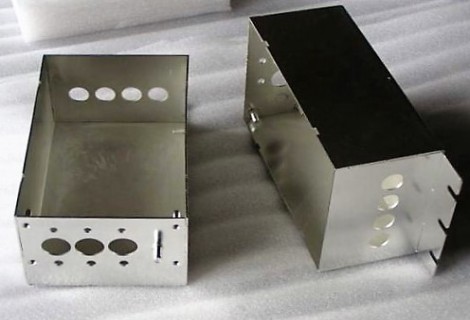

Metal Bending

Sheet metal bending or press brake forming, is a metal forming process that produce plastic deformation over an axis. Bending usually don’t generate change in the thickness of the sheet metal. In industry this process is used to impart strength and stiffness to sheet metal, to change part's moment of inertia or to improve products appearance.

To carry out this process is often used a punch and a die. Punch and die more common materials are gray iron and carbon steel. To apply necessary force a press is needed. The punch, die and press assembly is called press-brake.

Sheet metal bending process often use standard tooling for the punch and die, allowing a low initial cost and suitability for low to mid volume production. For specialized bending operations custom tooling can be used but the cost increases. The tooling material is chosen based on the volume of production, sheet metal material, and degree of bending.

There are a lot of types of bending process as below.

- Air bending

- Bottoming

- Coining

- Three point bending

- Folding

- Wiping

- Rotatory bending

- Roll bending

- Joggle bending