EDM

EDM or Electric Discharge Machining is a machining process, which consist on remove material from work-piece by electric discharges. The electrode is a very important part of the process. It is a good conductor. It is coated with graphite to improve wear resistance. The size and shape of this piece can be quite varied.

During the process, it generates an electric arc between the work-piece and the electrode. This arc reaches a high temperature that produce a crater on the work-piece to develop the final component.

To carry out this process usually the two parts, electrode and work-piece, are immersed in a dielectric (electrically non-conducting) liquid which is circulated to flush away debris and permit a higher control of machining temperature.

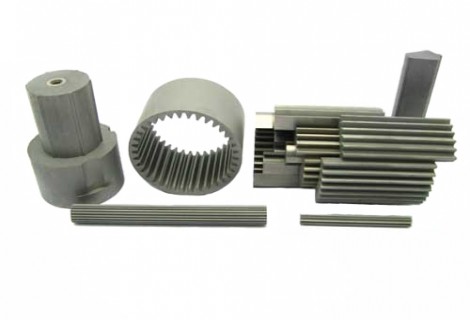

MATERIALS AND PRODUCTS

EDM can cut intricate contours or cavities in any material that will conduct electricity. But more common materials machining by EDM are:

- Steel

- Titanium

- Hastelloy

- Inconel

Most common products made by this operation are:

- Injection plastics die

- Cutting dies

- Tools

- Sintering dies

Especial applications:

- Production applications

- Aviation

- Nuclear Etc.